Prioritizing machine safety in industrial automation environments includes installing safety devices and solutions, providing comprehensive training, and keeping up with the continuous improvement of safety practices. Electro-Matic can assist in navigating the process of ensuring machine safety, minimizing the risks for both machinery and employees. In addition to Fortress Safety solutions, we provide a wide range of machine safety products.

Flexible Safety Solution: Configurable to Your Every Requirement

Topics: Industrial Automation, Electro-Matic Products, News

Sculpting the future: speeding machine, digital transformation

Fueled by visionary thinking and ingenuity, TARUS remains the leader in car design studio solutions. To maintain market dominance and meet accelerating customer demands, TARUS owners—and brothers—Dave and Doug Greig realized they needed to elevate and enhance the capabilities of their clay milling machines.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

Limited Time Offer! Get Started & Save Money with Siemens Hardware & Software Kits

Get your starter kit now! The starter kits are available for all devices from 7 to 22 inch. In addition to the device itself, they contain the engineering software as well as all the accessories you need to get started smoothly. Start with the limitless realization of your visualization ideas now.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

Upgraded ability of Fortress RFID readers

Fortress is dedicated to being world class innovators and the partner of choice for their customers. Electro-Matic is the exclusive distributor for Fortress Safety in Michigan, ensuring top-notch safety solutions for your needs.

Topics: Industrial Automation, Electro-Matic Products, News

Control and Operate with the SIMATIC WinCC Unified System – from visualization up to vertical integration

SIMATIC WinCC Unified is the latest visualization software in the TIA Portal, which is designed to optimize operator guidance, to support in the planning and traceability of production processes, provides flexible access to all data and provides efficient tools for analysis and minimizing downtime.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

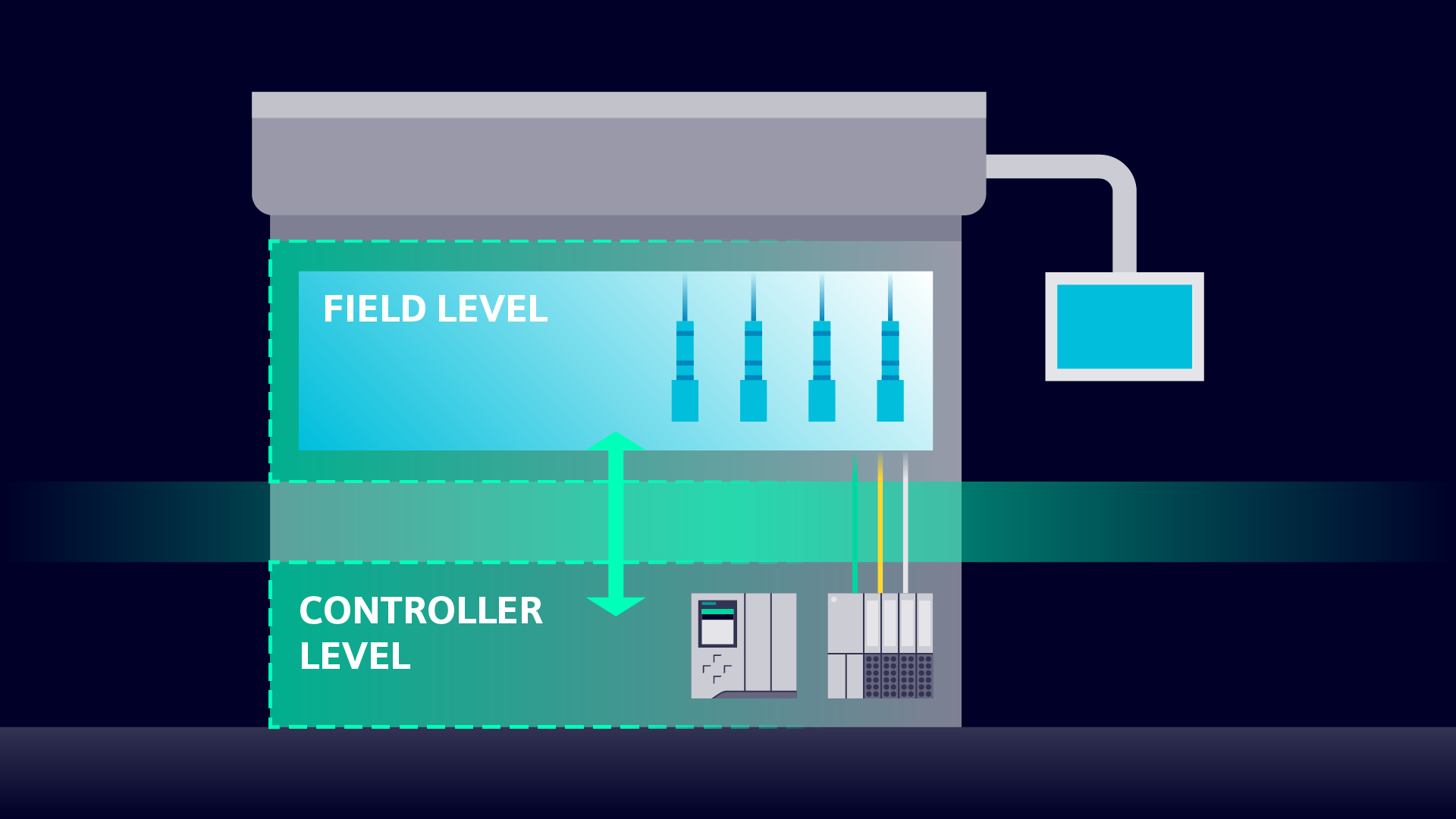

Field connectivity involves the connection of all field devices to central machine control. This includes the easy integration of sensors via standardized I/O interfaces in order to connect the field level to the superordinate control level.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

Remote Operation of Stand-alone Systems via Cellular Networks

Remote access makes it possible to securely access a machine from another location for purposes of commissioning or service. This means that the experts necessary for commissioning or modifying machines no longer have to be present on site. If a machine fails, a precise diagnosis and expert support are vital for quickly getting the system running again. Remote access also allows you to operate and maintain geographically distributed systems reliably and transparently, even in hazardous, isolated, or contaminated environments.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

Standardization has many facets and encompasses different products, processes, and tools. It can be implemented in any industry. Those companies that do nothing about implementing it may not understand the potential of standardization. An appropriate advice on standardization can open many doors and ensure a holistic approach for a given client. Those that may be pursuing standardization approaches or have implemented standardized solutions could benefit from continuous improvement. There is always room for optimization as standardization is a never-ending theme and the market and innovation change very quickly.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

The new PowerScan 9600 DPX industrial handheld scanner from Datalogic is best for traceability applications in Automotive, Aerospace, Tires and Electronics.

Topics: Industrial Automation, Electro-Matic Products, News

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"