In 2025, manufacturers are prioritizing sustainable practices, especially in the energy-efficient cooling of industrial enclosures. Key trends influencing this shift include the adoption of smart technologies, integrated cooling solutions, and the digitalization of design processes.

Trends to Impact Sustainable Industrial Enclosure Cooling in 2025

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

In a world driven by technology, innovation, and problem-solving, there’s no better way to prepare the next generation for success than through hands-on experience. FIRST Robotics is a global organization that does exactly that—empowering students to develop STEM skills, teamwork, and creativity through competitive robotics challenges.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

TIA Portal, Version 20 offers innovative features and enhancements that streamline industrial automation processes, as well as increasing flexibility, simplifying workflows and boosting efficiency, resulting in faster project development.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

To achieve the highest level of software quality, functions should be simulated and tested during the configuration and engineering phase. With SIMATIC S7-PLCSIM Advanced, virtual controllers can be created to simulate S7-1500 and ET 200SP controllers and used for extensive function simulation. In addition, the virtual controllers can also be tested and validated in the context of a system/machine. An extensive API is available for connection to plant/machine simulations.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

Increase Serviceability of Programming Code with TIA Test Suite

StyleGuide Conformity Using StyleGuide Checker

A uniform programming Styleguide containing naming conventions, comments, and other features leads to a better readability and code administration. The TIA Portal Test Suite offers a Styleguide Checker to guarantee code conformity to predefined rules and offers test results for reporting.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

Make the Shift from Reactive to Proactive Maintenance with Siemens Xcare

Siemens’ new Xcare program empowers you to maximize the performance and longevity of your automation equipment with a proactive approach to maintenance.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

This is a phase-out announcement for the Siemens VL UL (150-1600A) molded case circuit breaker (MCCB) portfolio, which includes all frame sizes and interrupting ratings along with associated exclusive accessories.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

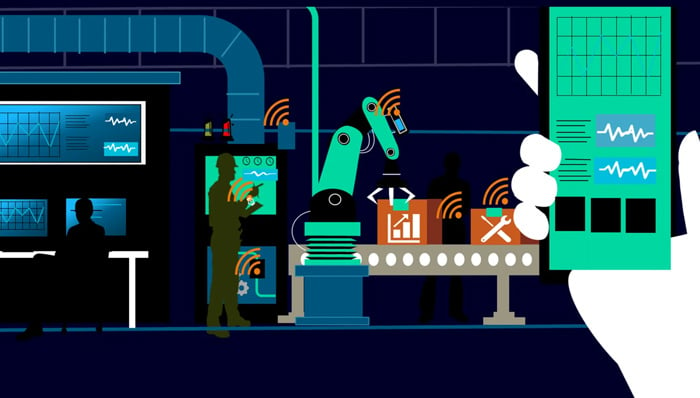

The need to shorten lead times for new machine manufacturing while maintaining flexibility for quick expansions is increasingly important. Advancing digitalization demands higher data throughput in production and IT exchange. Plant operators aim for higher automation to boost productivity, requiring easy machine integration and standardized data exchange interfaces. This increases the load on communication systems within and between machines. Global customers necessitate consideration of local conditions in machine design.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

Mechanical engineering is characterized by many challenges today. Increasing digitalization brings an increase in the speed of change, while the lead time for the introduction of new products steadily decreases. The productivity rate of a machine should be as high as possible, flexibly convertible to other product lines, with reduced downtimes.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"