A Virtual PLC is a software-based version of a traditional PLC. Instead of residing on a dedicated piece of hardware, it operates in a virtualized environment—typically running on industrial PCs, edge devices, or cloud platforms. The software replicates the functions of a physical PLC, such as real-time control, input/output (I/O) handling, and communication with field devices.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

What is the future of data centers? It’s a compelling question — mainly because, at first glance, data center design might seem fairly fixed. After all, the basic purpose remains the same: housing IT racks that generate heat, which must be managed to maintain efficient computing performance.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

Siemens and Electro-Matic are proud sponsors of FIRST Robotics, supporting teams like the Hybrid Hornets in their mission to inspire and develop the next generation of STEM leaders. Our sponsorships help provide students with the resources, mentorship, and opportunities needed to excel in engineering, programming, and teamwork.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

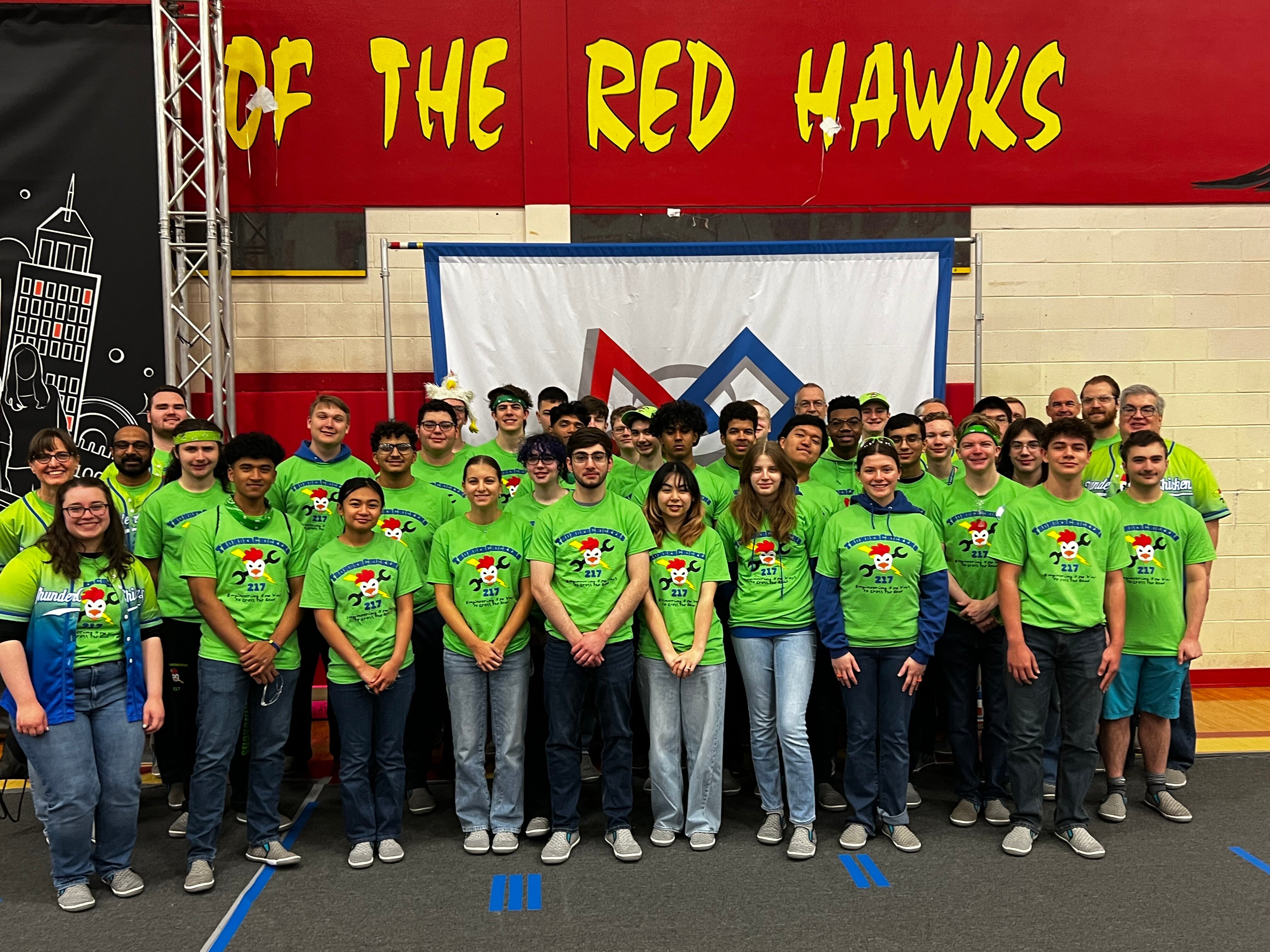

FIRST Robotics team #217, the ThunderChickens, consists of 28 students from all four high schools in the Utica Community Schools district. Siemens and Electro-Matic are proud sponsors of FIRST Robotics, supporting the innovation and success of teams like the ThunderChickens. As one of the many outstanding teams in the program, the ThunderChickens exemplify the power of STEM education, teamwork, and community outreach.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

Siemens and Electro-Matic are proud sponsors of FIRST Robotics, supporting the innovation and success of teams like the Knight Riders. As one of the many outstanding teams in the program, the Robostangs exemplify the power of STEM education, teamwork, and community outreach.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

We’re gearing up for the highly anticipated 2025 Automate Show, and we’re excited to share that many of our top manufacturing partners will be exhibiting

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

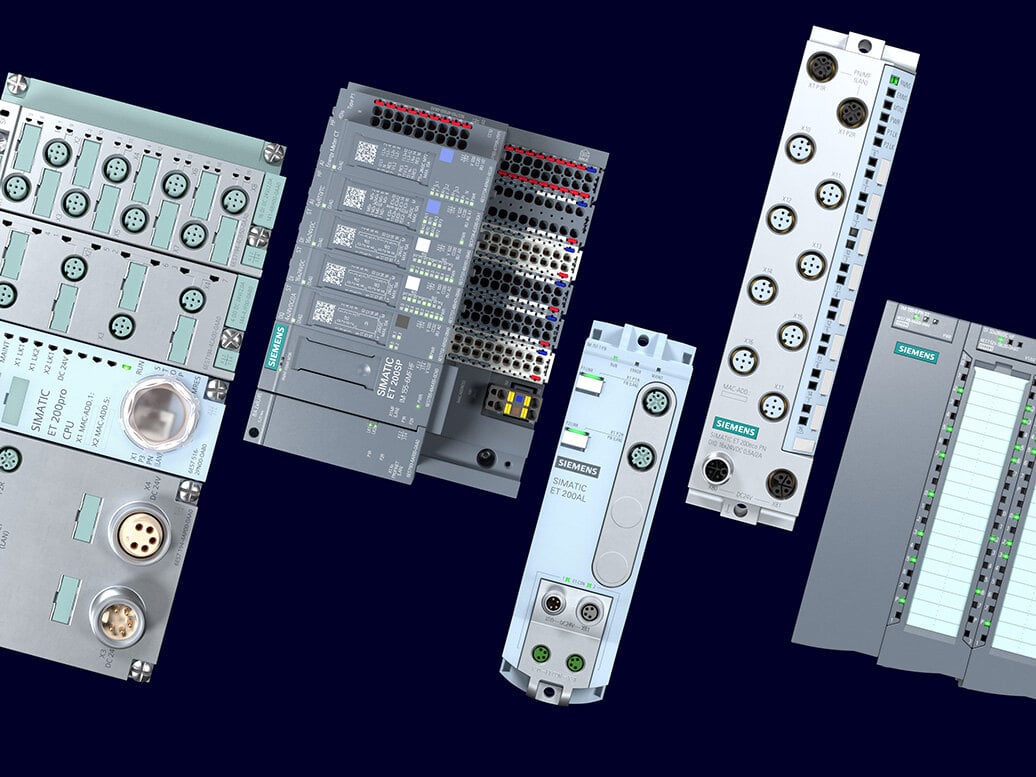

Machine Connection and Integration: Automation Needs an Integration Concept

The need to shorten lead times for new machine manufacturing while maintaining flexibility for quick expansions is increasingly important.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

The Northville Robostangs, Team #548, are a dedicated group of 76 students from Northville High School who share a passion for robotics and innovation. Siemens and Electro-Matic are proud sponsors of FIRST Robotics, supporting the innovation and success of teams like the Northville Robostangs. As one of the many outstanding teams in the program, the Robostangs exemplify the power of STEM education, teamwork, and community outreach.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

Networking, Reliability, Performance, and Data Transparency in Automation

Mechanical engineering is characterized by many challenges today. Increasing digitalization brings an increase in the speed of change, while the lead time for the introduction of new products steadily decreases. The productivity rate of a machine should be as high as possible, flexibly convertible to other product lines, with reduced downtimes.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

The Next Generation of Basic PLCs.

The SIMATIC S7-1200 G2 delivers with upgraded performance, optimized motion control, advanced machine safety, and greater data transparency.

Topics: Industrial Automation, Electro-Matic Products, News, "SIEMENS"

.jpeg)