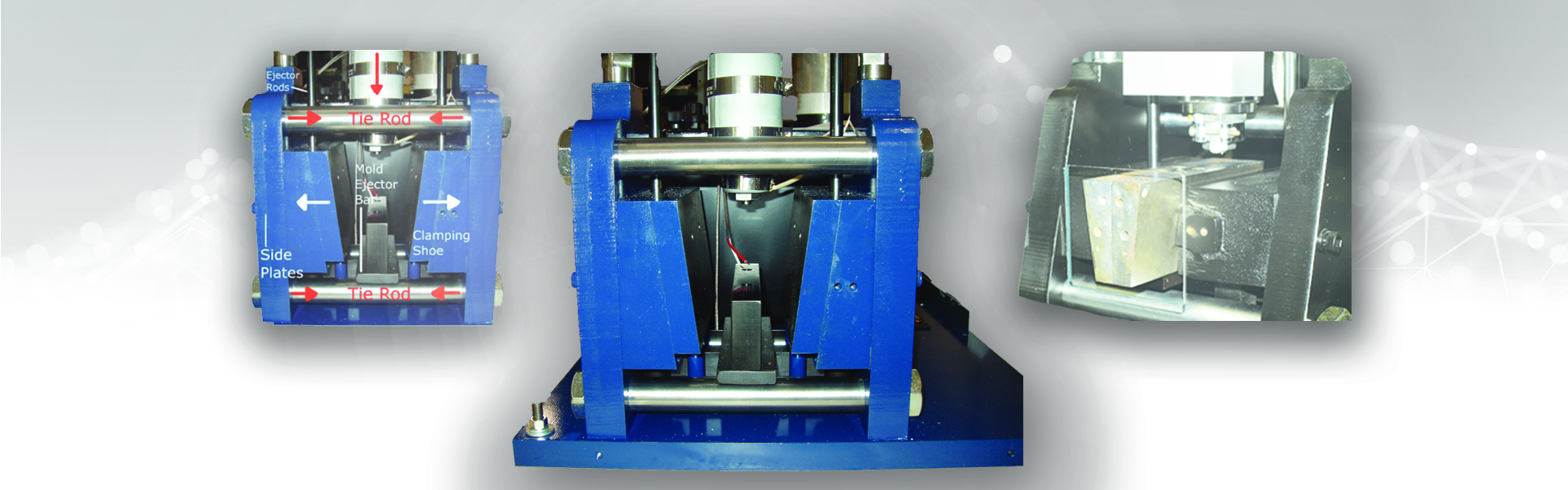

What if I told you that bigger is not always better? Many engineers know that this is the case when it comes to injection molding machines. Larger injection molding machinery is less portable, more difficult to house and typically requires more maintenance. If a machine exists with the same clamping force, half the footprint at a lower cost, why wouldn’t you use it? A superior design utilizing mechanical advantage makes this possible. In this blog we’ll show you how mechanical advantage works, and how the V-Mold can reduce the footprint and costs of plastic injection molding.

Using MA to Reduce Footprint of Plastic Injection Molding Machinery

Topics: Injection Molding

Prototyping Plastic Parts with Vertical Injection Molding Technology

Idea, product concept, initial design, prototype, final design, bridge production, market feedback, and final production are all phases that a new product may go through before it can be mass produced and sold successfully. Moving through these various phases quickly and economically is critical to the success of a new product launch. Vertical Injection Molding Technology should be considered as an efficient solution to both prototyping plastic parts and bridge production phases of the new product launches. This technology enables you to prototype plastic parts more easily and move to full production faster.

Topics: Injection Molding

Utilizing injection molding machines for low volume manufacturing requires machinery with the proper performance features, quality, and value. MPM injection molding machinery offers a unique feature set in a simple robust design at a competitive cost, making it an optimal machine for low volume injection molding applications.

Topics: Injection Molding

How to Reduce Injection Molding Costs with Low-Volume Injection Molding

We all face the challenge of reducing manufacturing or product costs. One key to success is having the right tools. You could use a sledge hammer to hang a picture, but a tack hammer is no doubt the better choice. When developing plastic parts and moving from design to a working model prototype, you need the manufacturer’s version of a tack hammer for the job. Using low volume injection molding (LVIM) can significantly reduce injection molding costs in a variety of ways.

Topics: Injection Molding

From specialized parts to new designs to brand new products, Low Volume Injection Molding is helping many businesses bring revolutionary products from design to production. There are many benefits to Low Volume Injection Molding (LVIM), and many reasons engineers add LVIM machines to their facilities. This list describes nine reasons why you should consider LVIM.

Topics: Injection Molding

ISO 9001 for quality management systems is the most widely used international standard in the world. Developed to give organizations a reliable, uniform framework for their quality management systems, it’s a signal to businesses around the world that their suppliers and partners prioritize quality. For essential products—like servo motor cables—that can put profits, equipment, and staff safety on the line if they are improperly constructed, ISO 9001 certification gives businesses security and confidence.

Electro-Matic Integrated vs Siemens Motion Connect Cable Assemblies

When seeking replacement cable assemblies, many engineers find themselves with a difficult consideration; should they wait for a cable they know will work, but sit through endless OEM lead times? Or order a third-party cable with quick-turnaround, but uncertain performance? Concern for cable integrity is understandable, but third party cables can supply the same performance and utility as original cables.

Our servo motor cables assemblies go head-to-head with Siemens motion connect cable assemblies to show just how the two compare.

5 Ways to Customize Servo Motor Cables For Improved Functionality

The following are five servo motor cable assembly modifications that we’ve frequently conducted. These changes may help you find the perfect fit as well.

3 Ways To Replace Servo Motor Cables Without The Manufacturer

A missing or damaged servo motor power or feedback cable can create significant downtime and hurt your company’s bottom line. A single servo motor cable, that is unavailable prior to a required ship date, can have a major impact on a customer relationship, or result in a late shipment penalty fee.

Manufacturers and suppliers of servo motor-based Motion Control Automation, work hard to keep the right servo motor cables on hand. As effective as these manufacturers have been at making on-time deliveries or responding to your emergencies, sometimes you have an urgent need for servo motor cables where "available yesterday" is not fast enough.

Industrial control panel wiring and design standards have changed in 2018 to facilitate international regulatory compliance and to accommodate new technologies. Most notable changes have been made to UL508A, now UL 60947-4, NFPA79, and NFPA70. To keep operators safe, protect equipment and maintain high quality standards, engineers need to know how to adapt and implement these new regulations.

Topics: Electro-Matic Products