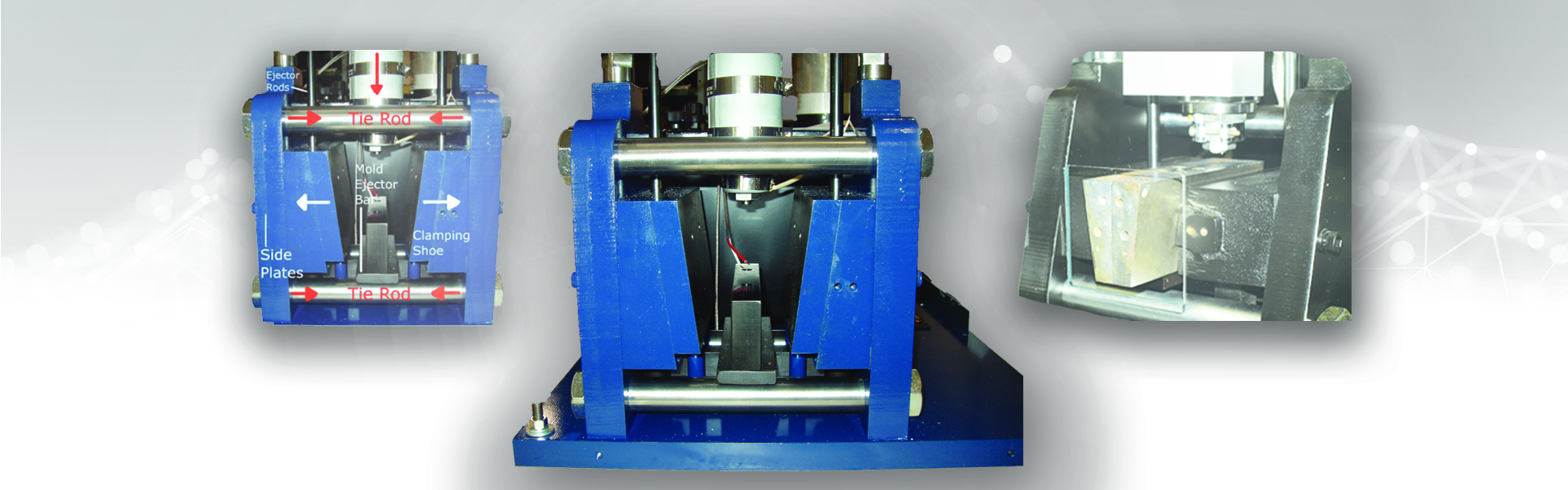

What if I told you that bigger is not always better? Many engineers know that this is the case when it comes to injection molding machines. Larger injection molding machinery is less portable, more difficult to house and typically requires more maintenance. If a machine exists with the same clamping force, half the footprint at a lower cost, why wouldn’t you use it? A superior design utilizing mechanical advantage makes this possible. In this blog we’ll show you how mechanical advantage works, and how the V-Mold can reduce the footprint and costs of plastic injection molding.

Using MA to Reduce Footprint of Plastic Injection Molding Machinery

Topics: Injection Molding

Prototyping Plastic Parts with Vertical Injection Molding Technology

Idea, product concept, initial design, prototype, final design, bridge production, market feedback, and final production are all phases that a new product may go through before it can be mass produced and sold successfully. Moving through these various phases quickly and economically is critical to the success of a new product launch. Vertical Injection Molding Technology should be considered as an efficient solution to both prototyping plastic parts and bridge production phases of the new product launches. This technology enables you to prototype plastic parts more easily and move to full production faster.

Topics: Injection Molding

Utilizing injection molding machines for low volume manufacturing requires machinery with the proper performance features, quality, and value. MPM injection molding machinery offers a unique feature set in a simple robust design at a competitive cost, making it an optimal machine for low volume injection molding applications.

Topics: Injection Molding

How to Reduce Injection Molding Costs with Low-Volume Injection Molding

We all face the challenge of reducing manufacturing or product costs. One key to success is having the right tools. You could use a sledge hammer to hang a picture, but a tack hammer is no doubt the better choice. When developing plastic parts and moving from design to a working model prototype, you need the manufacturer’s version of a tack hammer for the job. Using low volume injection molding (LVIM) can significantly reduce injection molding costs in a variety of ways.

Topics: Injection Molding

From specialized parts to new designs to brand new products, Low Volume Injection Molding is helping many businesses bring revolutionary products from design to production. There are many benefits to Low Volume Injection Molding (LVIM), and many reasons engineers add LVIM machines to their facilities. This list describes nine reasons why you should consider LVIM.

Topics: Injection Molding