Customer

Paramount Tool Company designs and builds machinery, special equipment and work tool holding fixtures that meet a variety of manufacturing needs. As a custom machine builder in Holland, Michigan, we offer a range of manufacturing solutions to help you improve the safety, efficiency, and productivity of your factory. Please contact us with any questions you may have.

The Situation

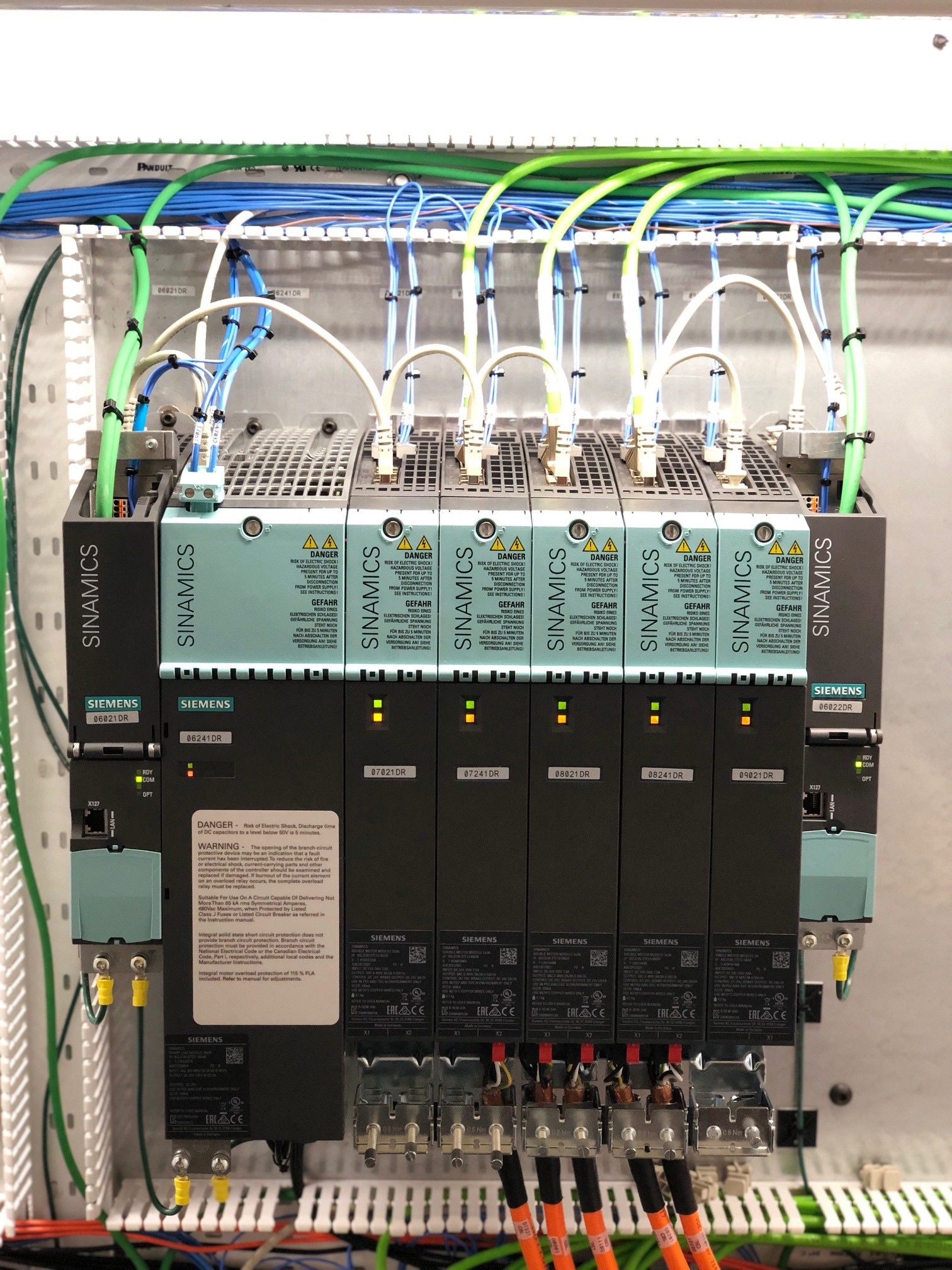

Paramount Tool needed servo motors, gear boxes, and drives that could precisely move/bend aluminum parts to match print. Electro-Matic's technical support/engineering department sized the components based on the customer’s requirements.

In a modern industrial automation scenario, whether we call it Industrial Internet of Things (IIoT) or Industry 4.0, the core premise is that devices on the plant floor generate massive amounts of data, which is collected, analyzed and converted into business value.

Upgrading your industrial PC is a significant investment of both time and money. Since Industrial PCs impact so many systems and processes, changes are met with an understandable level of hesitation. Many businesses forgo upgrades for too long, losing out on powerful performance improvements that can save time and reduce costs. So how do you know when it’s time to upgrade your industrial PC? Here are a few things to look for.

How to Choose an Industrial PC: Performance, Environment, Integration

As industrial systems become more complex, the need for more sophisticated controls increases. Choosing the right industrial PC can make the difference between a streamlined, independent system with pinpoint precision and a sluggish one requiring regular upkeep. Here’s what to look for when choosing an industrial PC that will serve you now and into the future.

Electro-Matic Products receives its 9th Siemens Bronze Eagle Award

As one of Siemens AG operating companies, Siemens Energy & Automation, Inc. provides complete electrical, engineering and automation solutions, along with the right products, software, and services to their clients worldwide. Their customers include some of the world’s largest and most respected companies in the industrial manufacturing and construction industries. Siemens technologies range from circuit protection and energy management systems, to process control, industrial software, and totally integrated automation solutions. The company also has expertise in systems integration, technical services and turnkey industrial systems. A dedicated team of more than 9,400 engineers, designers, field service technicians and diverse professionals are experts in their fields and draw on the global support and expertise of more than 400,000 professionals at Siemens-affiliated companies worldwide.

Business Excellence Eagle Award

Every year, Siemens presents their highest recognition award, the Business Excellence Eagle Award, to the top 25 performing companies or locations in the United States. All companies that earn the Business Excellence Eagle Award receive Siemens uniquely commissioned eagle statue, with a custom cast plaque recognizing the company and year that the award was earned. Additionally, recipients will receive a special celebration presentation hosted by their Siemens sales office.

As of 2019, Electro-Matic has now received nine of these prestigious Siemens awards. The Business Excellence Award comes with recognition for our outstanding sales achievement, as well as our commitment to mutual business development with Siemens. It is an honor to be recognized a total of 9 times since 2003, and we’re excited for what the future has in store for Electro-Matic’s amazing partnership with Siemens.

Topics: Electro-Matic Products, "SIEMENS"

Electro-Matic Ventures to Offer Multiple Solutions from Siemens PLM Software’s Digital Innovation Platform

Electro-Matic Ventures today announced that it will now offer the Teamcenter® portfolio, the world’s most widely used digital lifecycle management software, the Tecnomatix® portfolio, the industry-leading digital manufacturing software, NX™ software, a leading integrated solution for computer-aided design, manufacturing and engineering (CAD/CAM/CAE), and the Simcenter™ portfolio, a robust suite of simulation software and test solutions from Siemens PLM Software. Electro-Matic Ventures currently operates in Michigan, Northern Ohio and distributes Siemens’ TIA hardware and software products and solutions.

Topics: Electro-Matic Products, "SIEMENS"

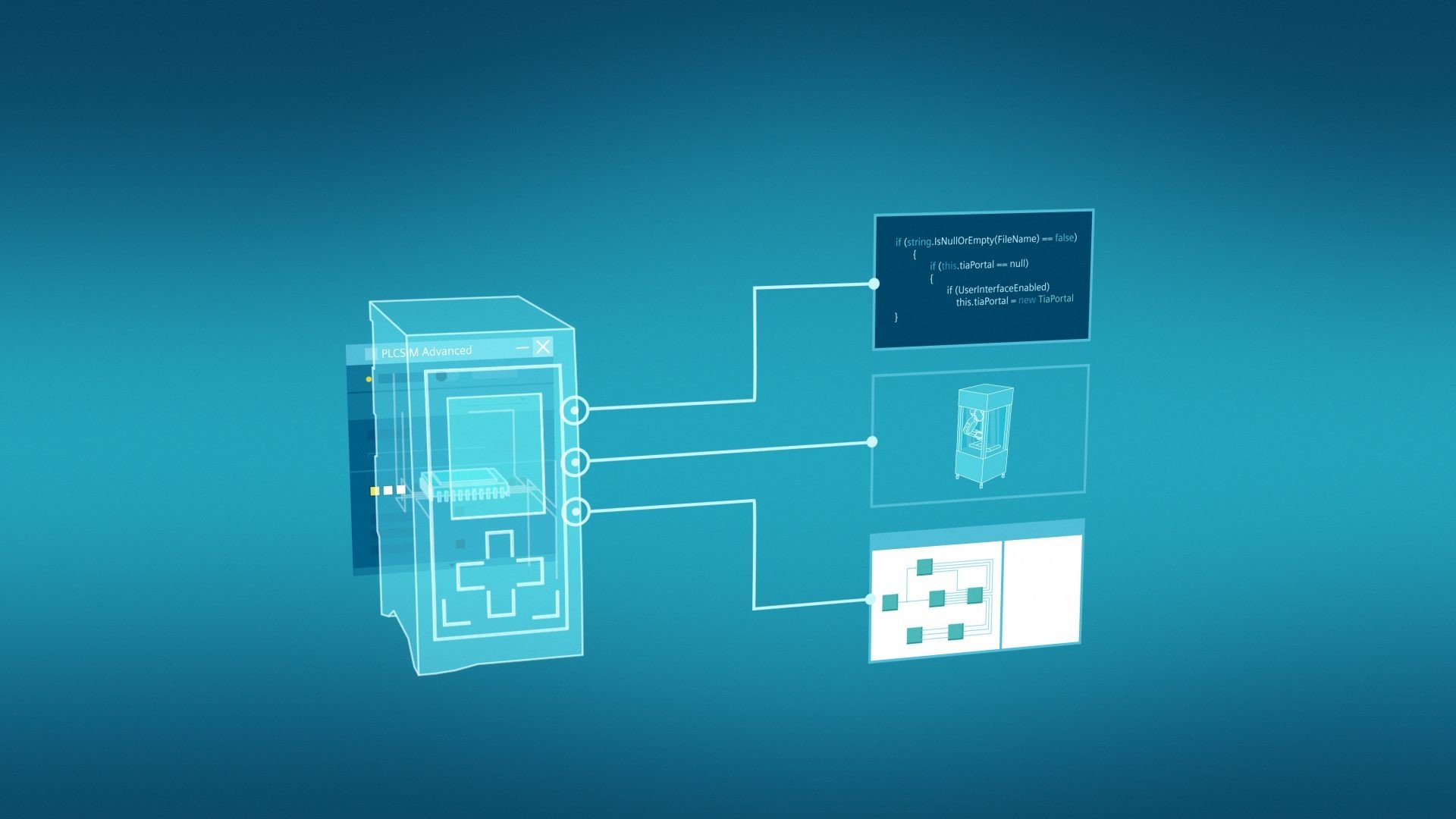

Siemens Expert Colm Gavin Gives MiA 2019 Attendees a Tour of the Digital Twin

The annual Manufacturing in America (MiA) event brings together hundreds of manufacturing and automation experts from all over the world to see, learn about, and experience the latest technology in the industry. Well-known for their commitment to innovation, Siemens consistently brings cutting-edge technology to MiA. We’re pleased to welcome Colm Gavin, an expert in digitalization and a 17-year Siemens veteran, back to MiA this year to present on Siemens’ latest innovations. His topic this year: commissioning production and perfecting manufacturing processes through a virtual copy—the Digital Twin. Let’s take a brief preview of the Digital Twin, and see what you can expect at this MiA presentation.

The Industrial Internet of Things (IIoT) and Industry 4.0 were buzzwords long before they presented real advantages or opportunities to most companies. Though they took some time to come of age, the many interconnected devices and the sophisticated networks and software connecting them are now real considerations for businesses large and small, worldwide, in 2019. As we enter the last stretch of the 2000’s second decade, the futuristic promises of the Industrial Internet of Things and Industry 4.0 have become realities. However, with these opportunities comes a number of risks.

Topics: Electro-Matic Products

The switch from UL508 to UL 60947-4, which were originally instituted in 2012 and became officially required in 2017, presented some challenges to manufacturers and engineers, especially those working with international clients. Siemens, Rittal, and other leading manufacturers have tried to make this transition easier, and facilitate international trade, by providing components that meet both UL and EIC regulations. Understanding that industrial engineers are responsible for not only their own safety, but also successful electrical design to protect the entire plant and all the staff, Siemens and Rittal have also provided information to help engineers navigate these changes and stay safe on the job.

Topics: Electro-Matic Products