Siemens Electro-Matic Industrial Engineering Lab Opens on LTU Campus

Electro-Matic is committed to ensuring the safety of our employees, customers, and partners as we continue to serve as an essential business. For your convenience, any additional resources you may need from us is listed here:

Festo is proud to announce its new external Festo Trends in Automation Podcast channel. Many of you enjoyed their internal podcast series, but now they have updated the content and opened it up to all external audiences. This gives customers and distributors the opportunity to listen to Festo content while at home or on-the-go. Each podcast is designed to provide an in-depth look into their product portfolio and provide features, benefits and tips that you may not get within a video or literature piece.

Electro-Matic is committed to ensuring the safety of our employees, customers, and partners as we continue to serve as an essential business. For your convenience, any additional resources you may need from us is listed here:

Overview

Because of the current pandemic with the COVID-19 virus, Datalogic has been approached regarding the cleaning of its' scanners and mobile devices. The following Bulletin will provide the necessary instructions on how to safely accomplish this task without harming the scanning devices.

On behalf of Electro-Matic Ventures, we want to thank you for your patience during this challenging situation and provide you with an update on our response regarding the Novel Coronavirus (COVID-19) pandemic.

More than Simple Cables

Headquartered in Bologna (Italy), TE.CO. was founded in 1982 on the idea of an added value customer service. Providing cable solutions is our business core. Our cables are cut to size, available in stock and best fulfilling the evolving market requirements. TE.CO. has chosen UL® Underwriters Laboratories to certify its cables complying with the main international certifications. A continuous growth allowed the company to become a leading, reliable business partner supplying special cables for industrial automation to international dealers, OEM’s, cable assemblies makers, wire harnesses manufacturers, panel builders, system integrators.

As a leading and reliable specialist business partner, Te.Co. supplies products for the industrial automation providing cut-to-size cables, according to the customers’ specifications, available in stock for prompt dispatch, and in respect of scheduled times frames. With more than 35 years of experience in this sector, we are able to provide a wide range of cables for various applications, such as static and dynamic installations, control solutions and power for servo-motor, signal transmission cables, data transmission, and BUS cables.

TE.CO. Business Model

- Our Salesforce is composed of Representatives and Area Managers spread across the national and international territories, who can provide qualified assistance and specific information material such as our catalog and information on our cables range for dynamic and static installation. All items listed in our catalog are available in our fully stocked warehouse. Te.Co. is aware of the importance of having both external and internal qualified and motivated employees capable of offering a quality product, just as it is aware that the Company’s productivity depends also on its employees’ well-being.

- We encourage the people who work with us to achieve new goals and we invest in personnel, supporting continuing education to expand employees’ know-how through conventional training programs and reverse mentoring to share new ideas and empower themselves, enriching professional and personal skills, capabilities. Investing in education is a small step that allows an enterprise to develop abilities in all areas, improve its productive performance, add to employees’ satisfaction and motivation and make people proud to be a part of the Company’s community.

- Due to implementing high technology products and in-house embraced digitalization processes, Te.Co. is a dynamic reality able to create a perfect combination for the growth of a state-of-the-art industrial model ensuring timeliness and traceability of information and increasing the efficiency and quality. Automating production processes all over the firm and our advanced Logistics, lead to reduce and minimize errors because technology is a key factor for any enterprise and effectively integrates different activities.

- Having an inner Technical Department allows us to give quick answers to clients’ requests and let them have detailed information enhancing the cables’ datasheets our customers can find on our website by searching the cable which suits them the most with our configurator, a very user-friendly tool making the visitor’s shopping experience unique and profitable.

- Moreover, a Marketing Department works on new projects, close to the Management and Sales Network, to reinforce Te.Co.’s brand awareness with the aim to have our products travel throughout the world.

To us, the MiA show provides Te.Co. with an amazing opportunity to take on and to overlook the American market. Planning work, making products, selling them, scheduling, participating in events, receiving awards and obtaining certifications are only a few of the things that make a company evolve, basing its daily matter on the idea of an added value customer service. This depends on technological innovation and on people: the sales force, employees and management who dedicate their time to the organization, with passion and commitment. Thanks to our partner Electro-Matic Integrated, we attend this event with an open-minded attitude and acting in a proactive way is necessary to face new challenges and seize new chances to grow.

We continuously strive to be innovative, to offer new cable families and to design alternative tailor-made solutions for the market. Visit us at booth #405 at MiA to discuss the features and key benefits of using Te.Co. special cables, and other cutting edge solutions for industrial automation applications that we have to offer you. To learn more about us, browse our website and download our Company Profile.

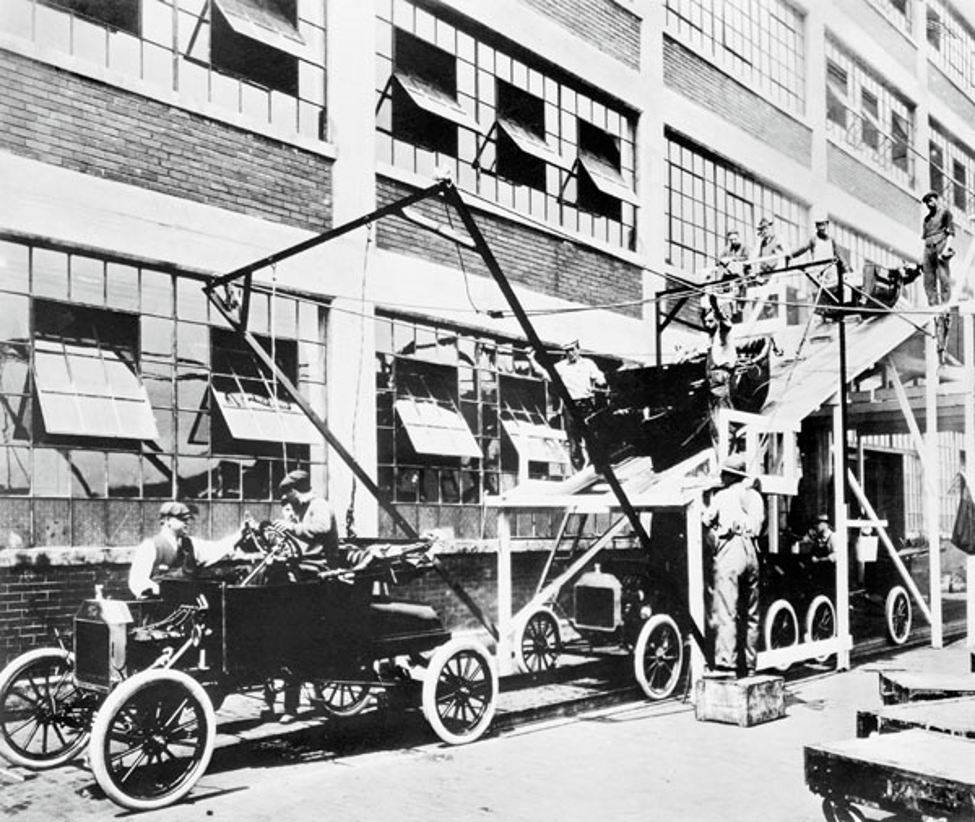

The Roaring’ 1920s, also known as the golden age of North America, was a decade of unprecedented economic growth and prosperity brought about by the rise of rapid technological advancements across all industries. It was the introduction of automation, human-automation in the form of Henry Ford’s assembly line, and the spread of electricity which made mass production attainable across all industries that precipitated the vast economic boom enjoyed by all in the 1920s.

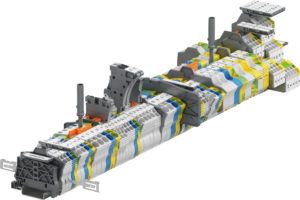

Electro-Matic Integrated is pleased to be distributing the TE Connectivity Entrelec brand of terminal blocks in Michigan, Indiana, Ohio and Western Pennsylvania.

Electro-Matic Products to be an Authorized MindSphere Reseller

Electro-Matic Products is excited to announce that it is now an Authorized MindSphere Reseller. This cloud-based, open IoT operating system from Siemens connects your products, plants, systems, and machines to develop robust industrial IoT solutions faster. It provides a wealth of data through advanced analytics and delivers numerous benefits from its open PaaS capabilities, closed-loop innovations with end-to-end digital twins, a world class partner ecosystem, and more. It connects real things to the digital world and provides powerful industry applications and digital services that help drive business success.