In today’s high-stakes manufacturing environment, especially within the automotive sector, precision isn’t optional. Processes like hot stamping, which shape high-strength, lightweight structural components, must operate within incredibly tight tolerances. Any deviation in temperature can compromise part integrity, lead to tooling damage, or fail critical metallurgy tests.

So how do manufacturers maintain control over such a volatile process? The answer: real-time thermal imaging—and Emitted Energy is leading the charge.

Why Thermal Imaging is a Game-Changer for Hot Stamping

Hot stamping requires heating boron steel blanks to austenitizing temperatures, rapidly transferring them to a die, and quenching the part to achieve martensitic transformation. But ensuring consistent temperature across the entire part is a major challenge.

Traditional tools like thermocouples and IR spot sensors only give single-point readings. This means they often miss thermal gradients or anomalies that occur across the full blank or tool surface.

That’s where Emitted Energy’s Thermal Process Monitoring System—powered by the FLIR A70 thermal camera—comes in. With full-field thermal visibility, engineers can now detect hot and cold zones in real time and take action before any damage is done.

Common Challenges in Thermal Validation

- Despite its importance, thermal validation often falls short due to outdated or manual processes. Key pain points include:

- Inadequate Thermal Visibility: Spot sensors only capture a single data point, missing broader thermal patterns.

- Undetected Thermal Drift: Oven performance can degrade over time, causing slow-forming issues that go unnoticed until parts start failing.

- Recipe and Maintenance Blind Spots: Subtle issues might still pass spec, but trend toward failure over time.

- Human Error: Manual checks vary between operators and don’t provide reliable repeatability.

- Lack of Traceability: Without timestamped thermal records, it's difficult to perform root-cause analysis when problems arise.

- Without real-time, image-based solutions, manufacturers risk higher scrap rates, increased rework, and costly downtime.

Enlighten+: Real-Time Thermal Intelligence

Emitted Energy’s Enlighten+ software, used in tandem with FLIR A-Series cameras, takes thermal imaging to the next level.

This powerful platform doesn’t just show heat—it transforms it into intelligent, actionable insight for manufacturing teams.

Key Features:

- Seamless Integration: Direct communication with PLCs and automation systems for uninterrupted operations.

- Advanced Analytics & Alarming: Set custom thresholds and get real-time alerts when conditions drift.

- Dynamic Parameter Tuning: Adjust thermal profiles for different parts, tools, or zones.

- Automated Inspection & Logging: Replace inconsistent manual checks with consistent, automated thermal scans.

- Proactive Detection: Catch issues like overheating dies or cold blank spots before they become defects.

- Optimized Feedback Loops: Use real data to fine-tune recipes, reduce cycle times, and streamline maintenance.

- Unlike passive monitoring, Enlighten+ functions like a digital thermal assistant—monitoring, analyzing, and alerting in real time.

How Thermal Cameras Work (And Why They Matter)

Thermal cameras detect infrared radiation from objects and translate it into high-resolution temperature maps. Unlike traditional sensors, which only measure a single point, these cameras provide a full-surface view.

Key Camera Components:

- Infrared Lens

- Microbolometer Sensor

- Calibration Algorithms (accounting for environment, background, and emissivity)

This makes them especially effective in demanding environments like hot stamping, where process control must be both precise and reliable.

Real-World Impact: Case Study Highlights

A global automotive OEM used Emitted Energy’s system to overhaul their thermal validation in a high-throughput stamping facility. The results were impressive:

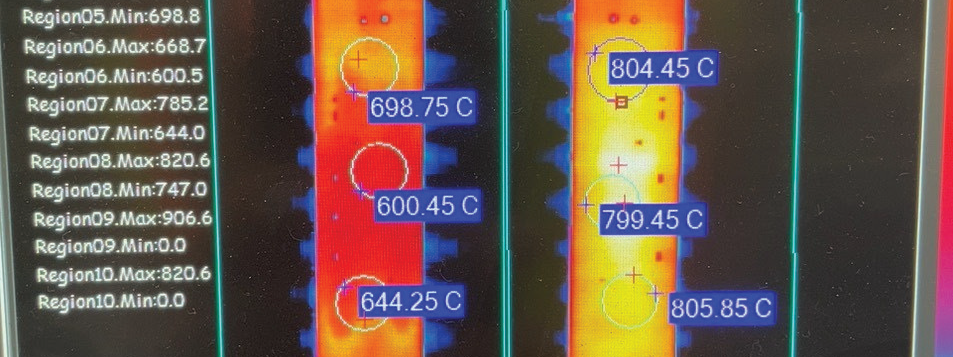

Problem 1: Cold Zone Detected

A blank showed a cool area (600–698°C), still within spec—but at the low end. Without thermal imaging, this anomaly would have passed unnoticed. With Enlighten+, the team adjusted oven settings and improved recipe accuracy.

Problem 2: Excessive Heat Buildup

Thermal scans showed uneven temperature distribution across parts, revealing die surface buildup. Maintenance restored uniformity and prevented further quality issues.

Problem 3: Inconsistent Cooling

Post-stamping images showed residual heat zones over 300°C—well above acceptable cooling levels. The system flagged die cooling inefficiencies, and teams quickly resolved blocked water channels.

The Result:

- Improved first-pass yield

- Reduced downtime

- Full traceability for quality audits

- Faster root-cause resolution

Smarter Manufacturing Starts with Better Thermal Insight

Thermal imaging is no longer a luxury—it’s a necessity for manufacturers aiming to stay competitive. Emitted Energy’s full-field solution, powered by FLIR technology and Enlighten+ software, offers:

- Real-time visibility

- Automated quality control

- Reliable traceability

- Reduced scrap and rework

- Optimized uptime

If you want to reduce waste, boost quality, and meet today’s stringent production standards, it’s time to look beyond the surface—and into the heat.

Contact us or your Account Manager for more information!